Major Maintenance

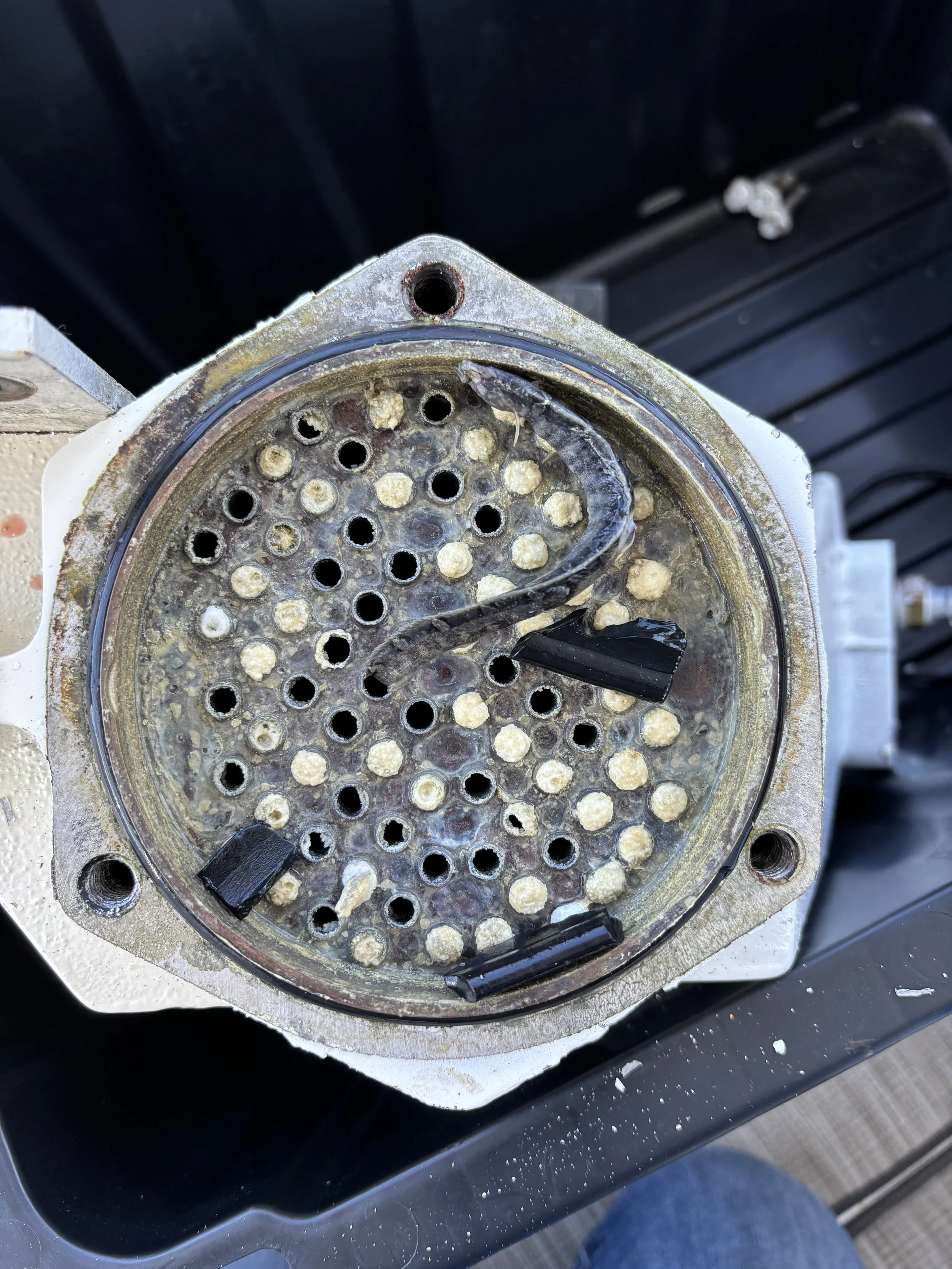

One of the most critical preventative maintenance tasks for Sea of Memories for the 24-25 off-season was a complete overhaul of her main engines’ cooling system. This is one of the biggest jobs we’ve tackled, but boy, she needed it! One of the key components to keeping her operating reliably is the seawater aftercooler that cools the turbo air before it’s charged back into the intake. These aftercoolers feature copper tubes that channel cold seawater through a block of fins that allow the air to pass over them. You can see from the below that her starboard main aftercooler was not in great shape with about 50% of the tubes plugged, some old bits of an impeller, and even a small fish.

Starboard aftercooler, before servicing. Home to some sea life and remnants of impellers past.

As the aftercoolers are one of the first components in the engine cooling system, a plugged up aftercooler will also result in poor cooling of the transmission as well as the main engine, restricting flow to the heat exchanger. This is why this maintenance is so critical and should be done every 2-3 years. From the records we found, the previous owner completed this service 7 years ago! Time to get to work.

Both aftercoolers and engine heat exchangers were removed from Sea of Memories and brought back to the H&L shop to complete the bulk of the tear down and re-build. The heat exchangers inside the aftercoolers were separated from the cases, descaled and degreased, and pressure tested. Aftercoolers were rebuilt ‘the Seaboard way’ to ensure in the next few years, this maintenance task is easier.

All of the critical cooling system components from both engines, plus some exhaust tubes needing replacement.

Both engine heat exchangers were descaled and end caps re-installed. All components were then re-painted and taken back to Sea of Memories for reinstall.

Additionally, we also took the opportunity to address several leaks on the port engine wet exhaust system. Several fiberglass exhaust tubes were found to be cracked, causing water to drip into the engine room and cause corrosion issues on the engine frames. New pieces were cut to length and installed. No more drips!

We also took the opportunity before reinstalling all of the cooling components and new exhaust tubing to address the extensive rust on the engine frame rails. Now that was a fun job!

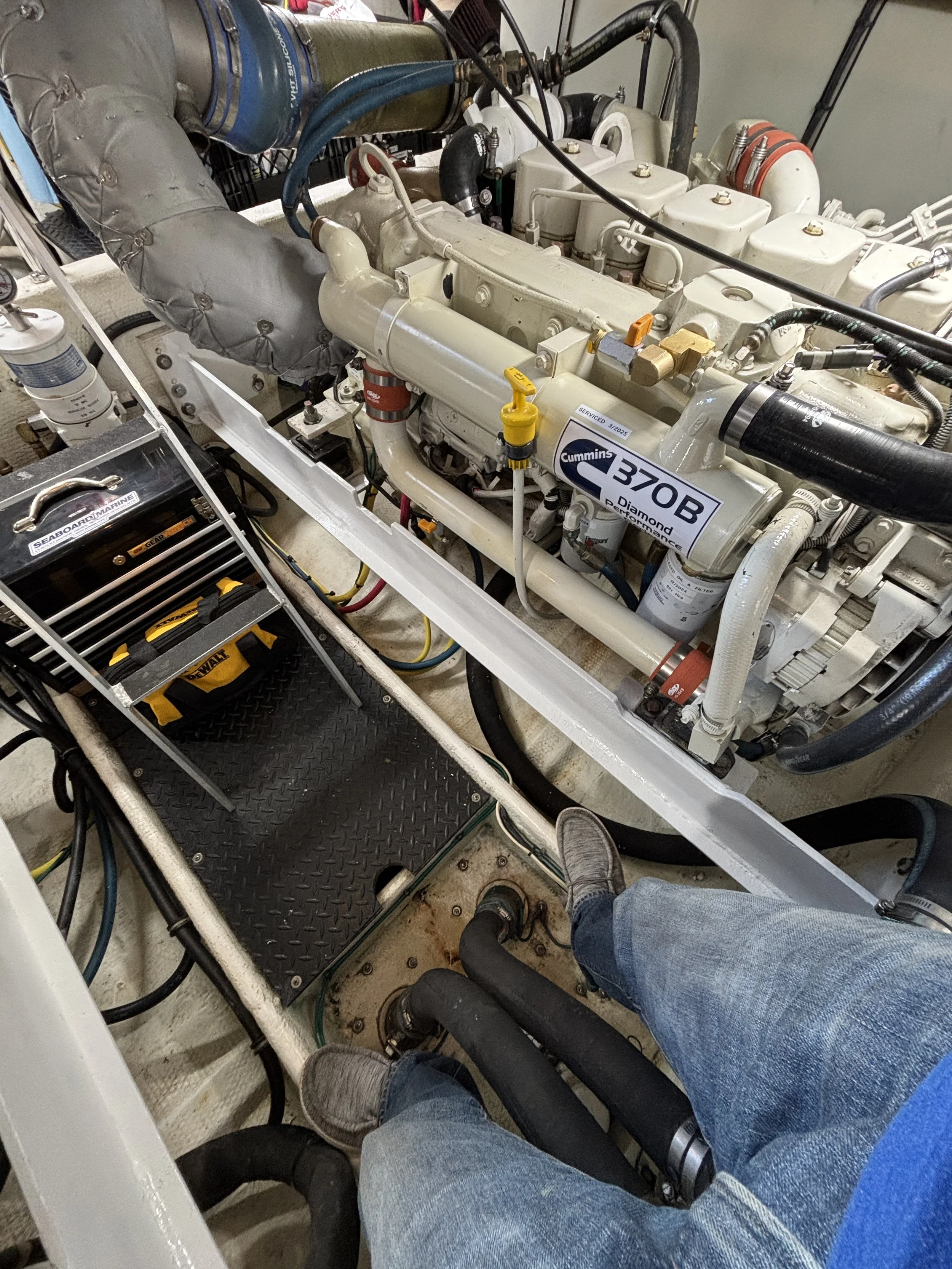

Nice and shiny engine room - freshly cleaned and painted cooling components and engine support rails.

Overall this was a huge evolution and the largest maintenance task we’ve undertaken to date. This work took 3 weekend aboard, 2 weeks in the shop, and over 70 hours, but it certainly paid off. It was clear this maintenance was way overdue. The engine room looks better than ever and Sea of Memories is more reliable than ever as we prepare for what is shaping up to be a very busy 2025 season.

It’s a really good thing we also like working on boats too, because there’s certainly plenty of opportunity for that. This one feels good to have complete though. Now on to the next project :)